Air Filter

An HVAC air filter is a crucial component in heating, ventilation, and air conditioning (HVAC) systems. It is designed to trap dust, dirt, allergens, and other particles from the air as it circulates through the system, improving indoor air quality and ensuring that the HVAC system operates efficiently.

Fiberglass Filters

Pleated Filters

High-Efficiency Particulate Air (HEPA) Filters

Electrostatic Filters

Activated Carbon Filters

Media Filters

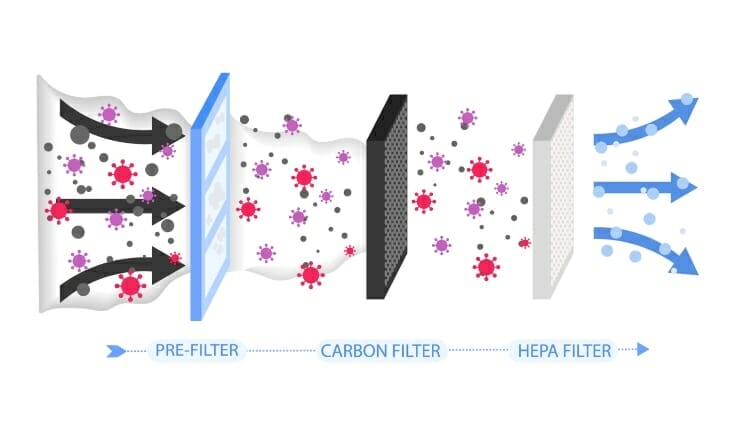

Carbon & HEPA Hybrid Filters

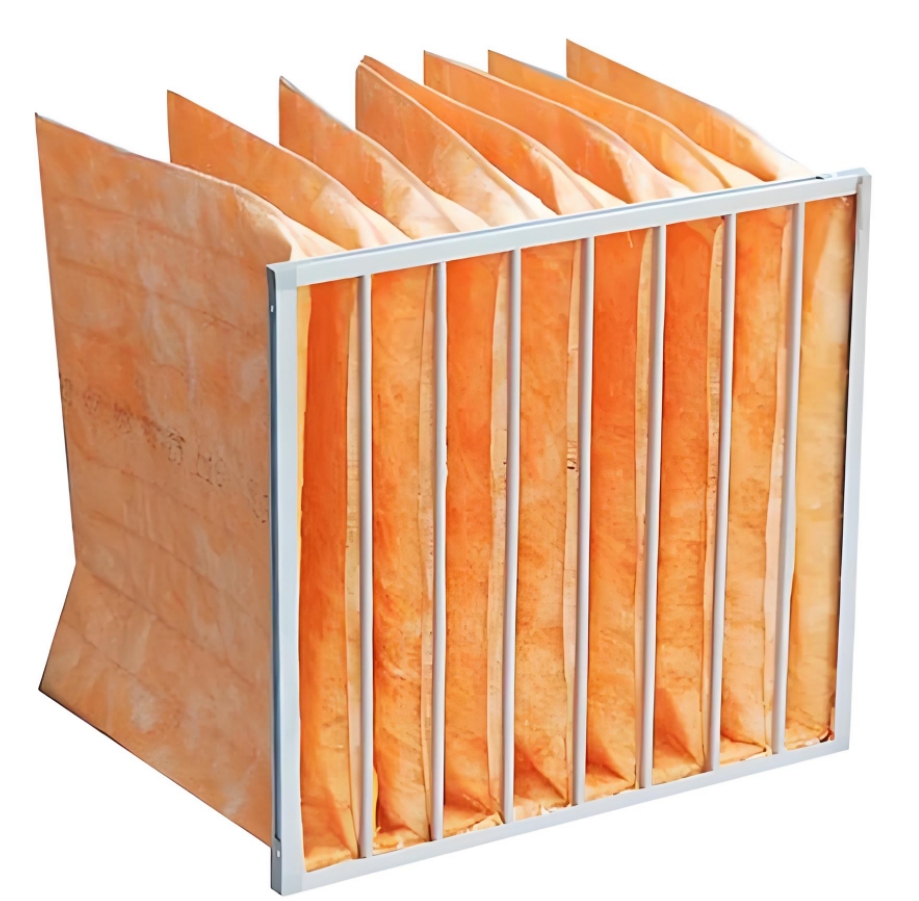

Bag Filters

Your Reliable Manufacturer of Air Filter

Air conditioner filter structure

The outer frame is cardboard, the filter material is non-woven fiber felt, folded filter material, and the back is metal square hole mesh for support, which is economical.

Air conditioner filter use

Pre-filtration of air conditioning and ventilation system for machine room, return air filtration for clean room of purification air conditioning, pre-filtration of high efficiency filtration, pre-filtration of air compressor.

Air conditioning filter classification

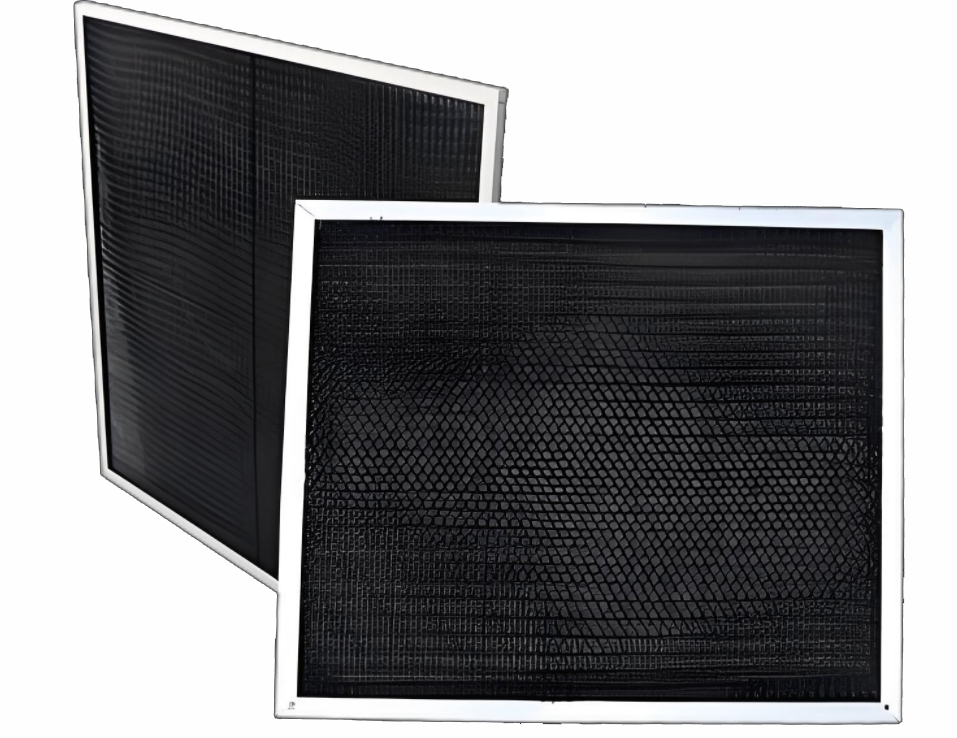

Primary air conditioning filter

Scope of application: applicable to the primary filtration of air conditioning system. Primary air filter is applicable to the primary filtration of air conditioning system, mainly used for filtering dust particles above 5μm. There are three styles of primary effect filters: plate type, folded type and bag type. The outer frame materials include paper frame, aluminum frame and galvanized iron frame; the filter materials include non-woven fabrics, nylon mesh, activated carbon filter material and metal hole mesh, etc.; the protective mesh includes double-faced sprayed iron wire mesh and double-faced galvanized iron wire mesh.

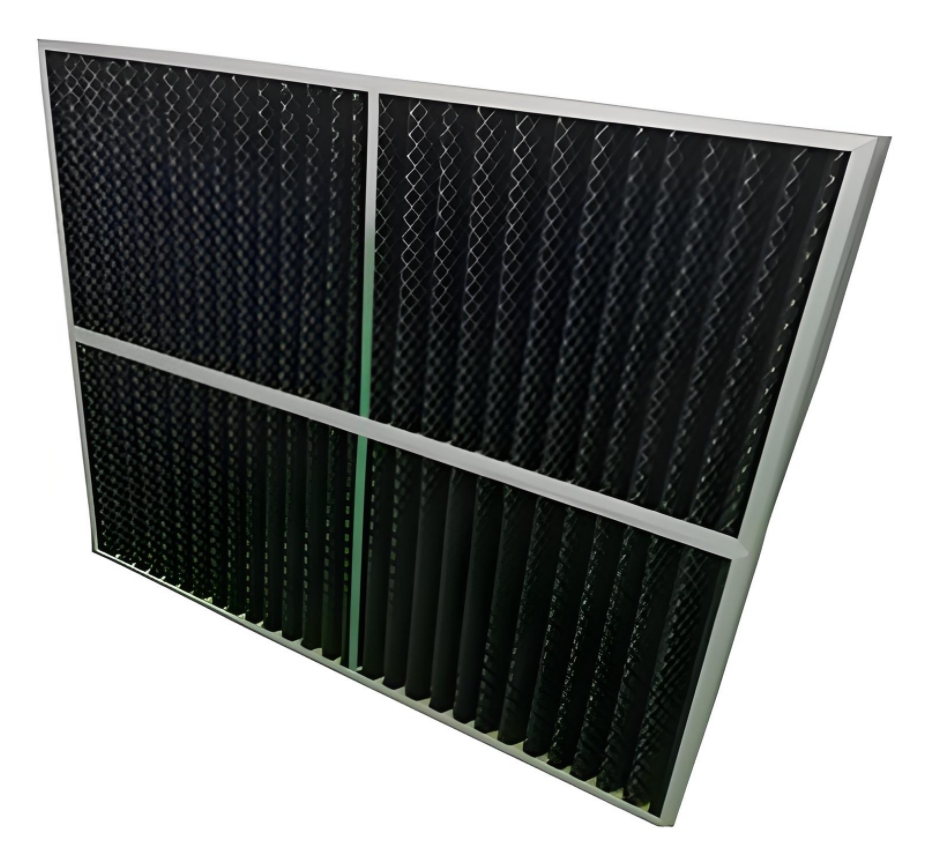

Medium-effect air-conditioning filter

Medium-effect filter is mainly used in central air conditioning and centralized air supply system. It can be used for primary filtration of air-conditioning systems to protect the next level of filters in the system and the system itself. In places where the requirements for air purification and cleanliness are not strict, the air processed by the intermediate-effect filters can be sent directly to the users. The medium-effect bag filter (bag filter) produced by our company has cold-plate spraying, galvanized plate and other forms of frames, and the filtering materials include non-woven fabrics, glass fibers, etc., with a filtration particle size of 1-5um and a filtration efficiency of 60-95% (colorimetric method).

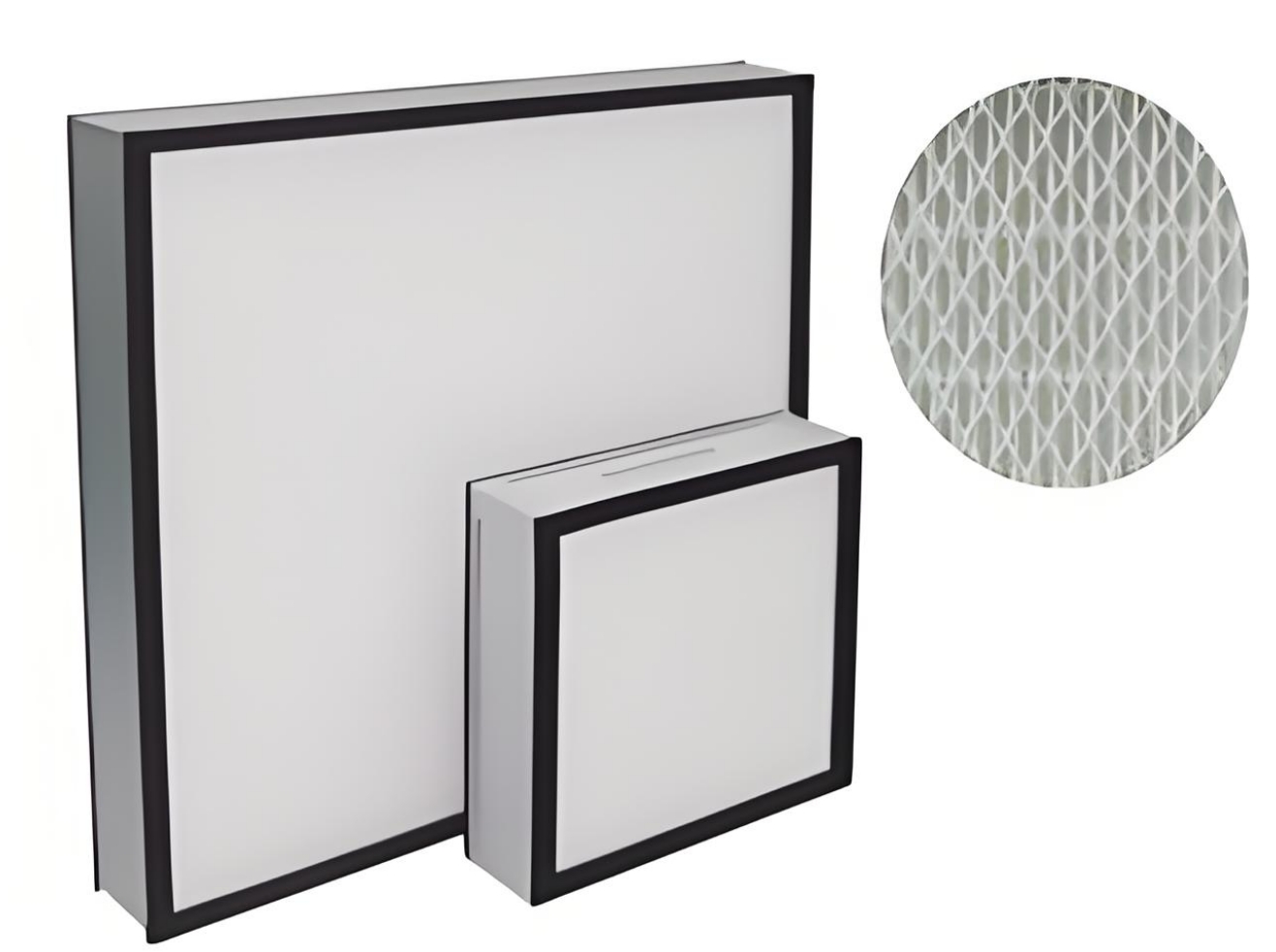

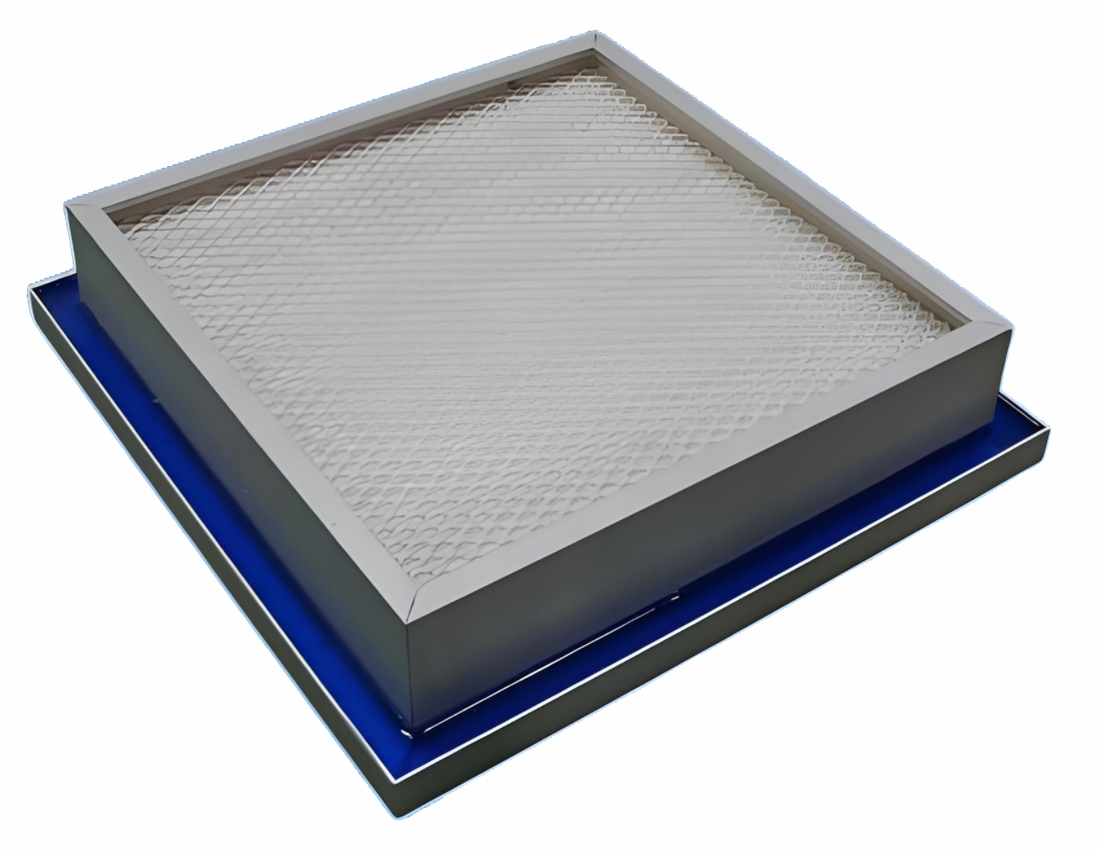

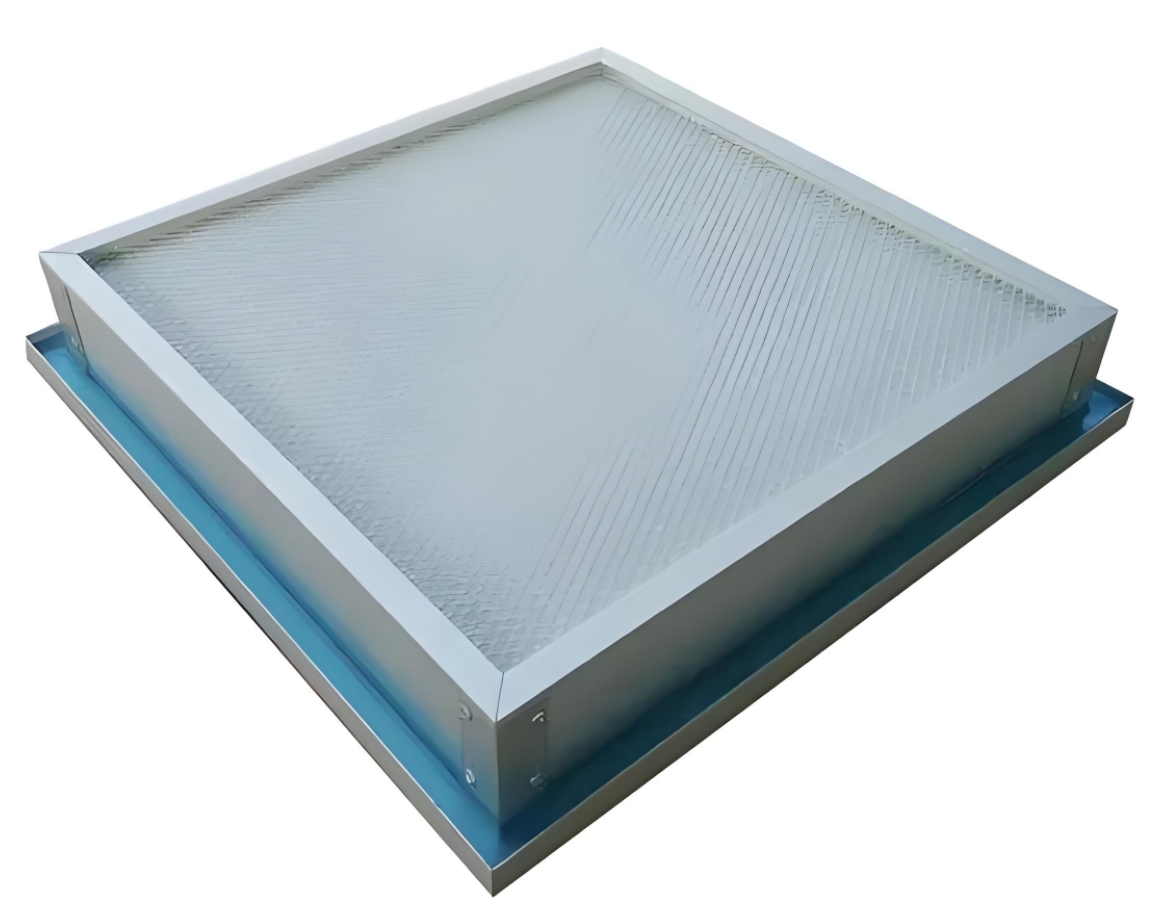

High-efficiency air conditioning filter

High-efficiency air filters are mainly used in the microelectronics industry, precision instrumentation, medical and health care, bioengineering, pharmaceutical and food industries and various types of clean rooms, clean tunnels, high-efficiency air supply outlets, purification benches, air showers, and other purification equipment, such as the final filtration of the air. The product adopts ultrafine glass fiber filter media, hot sol as separator, special aluminum profile frame, polyurethane two-component sealant, closed-cell sponge sealing strips, plastic spraying steel mesh even flow plate and so on after a strict process of refinement.

Final Resistance

Generally 260~320Pa

Efficiency specification from G2~G4

Detection Methods

The main basis for domestic high-efficiency air filter testing

GB/T 13554-2008 《High Efficiency Air Filter》,

GB/T 14295-2008 Air Filter,

JB/T 6417-1992 “Air Filter for Air Conditioning”,

GB/T 6165-2008 High-efficiency Air Filter Performance Test Methods Filtration Efficiency and Resistance.

Testing methods include: sodium flame method, oil mist method and counting method, with sodium flame method as the baseline method.

From the evolution of international HEPA filter testing standards, it can be seen that HEPA filter testing methods mainly include sodium flame method, oil mist method, DOP method, fluorescence method and particle counting method.

replacement cycle

Primary filters are generally replaced once every 2-3 months, every six months, so that the life of high-efficiency filters can generally be more than 2 years; but in order to protect the use of high-level filters to protect the latter and to ensure the safe operation of the clean room, many smart owners of the monthly replacement of the primary effect, every three months to replace the intermediate and sub-high-efficiency (or the end of the wind cabinet described earlier to choose a high-efficiency to do the protection of filters), which can ensure that high-efficiency filters 5 years (or even 10 years) more than the service life, and because the replacement of the new filter resistance is small, the air conditioning load is greatly reduced, and the cost of replacing the filter is much less than the cost of air-conditioning operation of the electricity required, frequent replacement of the pre-filter pre-filter is actually making the air-conditioning in the low-resistance load operation, saving a lot of money on electricity;

- Video

- Workshop

- Data sheet

- Material certificate

| Filter Type | Efficiency | Particle Size Captured | Common Use | Replacement Frequency |

|---|---|---|---|---|

| Primary Filter | Low to Medium (50-80%) | Large particles (dust, lint, hair) | Residential, Industrial HVAC | 1-3 months |

| Medium Filter | Medium (85-95%) | Smaller particles (pollen, mold spores) | Commercial HVAC, Offices, Healthcare | 6 months |

| HEPA Filter | High (99.97%) | 0.3 microns and larger (dust, allergens, bacteria, viruses) | Hospitals, Cleanrooms, Air Purifiers | 1-3 years |

Primary filter

Primary filter is the primary filter in air conditioning system, which is mainly used to filter dust particles above 5μm, and is one of the key components to ensure air quality and normal operation of the system.

Medium Filter

Medium-effect filters belong to F series filters in air filters, mainly including bagged and non-bagged types to meet different air purification needs.

HEPA filter

The core equipment of the air conditioning purification system, the high-efficiency air conditioning filter is used in the terminal of constant temperature and humidity purification air conditioning,

Help to Find Your Cleanroom Related Products

-

空气淋浴器

US$

Min. Order: -

模块化洁净室

US$

Min. Order: -

Downflow Booth

US$

Min. Order: -

Clean bench

US$

Min. Order: -

Air Filter

US$

Min. Order: -

Cleanroom Wall Panels

US$

Min. Order: -

Pass Box

US$

Min. Order: -

FFU

US$

Min. Order:

Can a HEPA filter be washed?

HEPA filters are not washable. HEPA filters are made of delicate materials and are designed for single use, not suitable for washing. Cleaning may damage the filter material, resulting in reduced filtration efficiency.

Replace the filter. In order to maintain efficient filtration performance, HEPA filters should be replaced regularly. It is generally recommended to replace them every 6 to 12 months, depending on the usage environment.

What do HEPA filters not remove?

Gases and Vapors: HEPA filters do not remove gases, fumes, or vapors like volatile organic compounds (VOCs) or odors, as they only filter out solid particles.

Very Small Particles: While HEPA filters capture 99.97% of particles down to 0.3 microns, they may be less effective at trapping particles smaller than this, such as some nanoparticles.

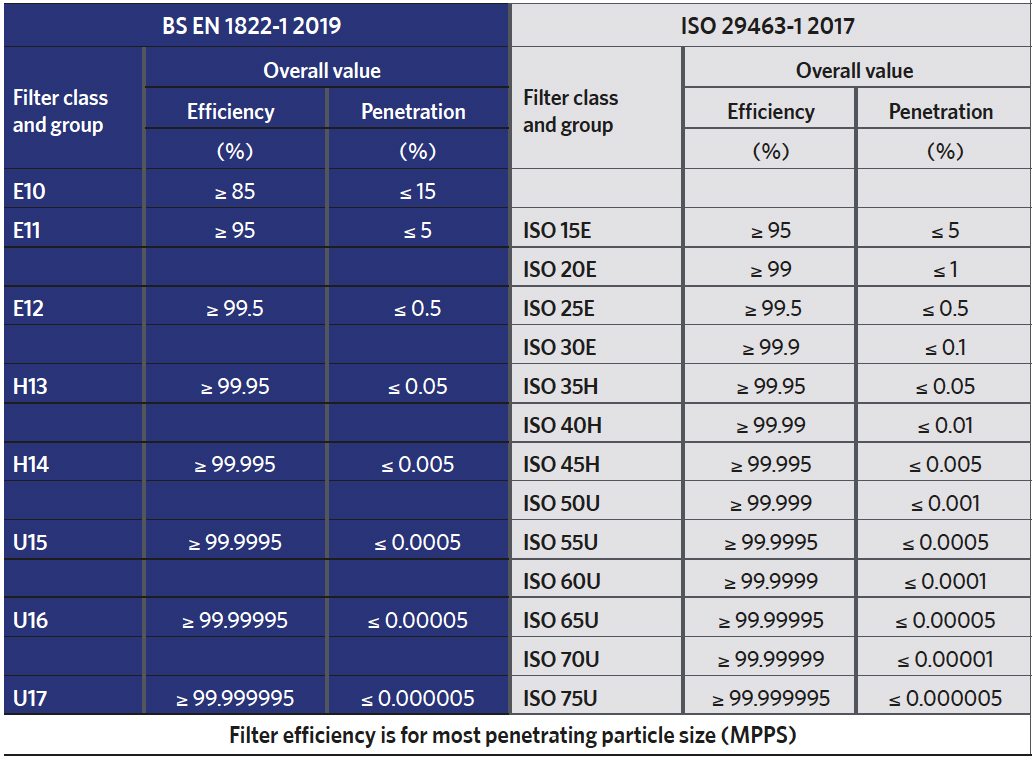

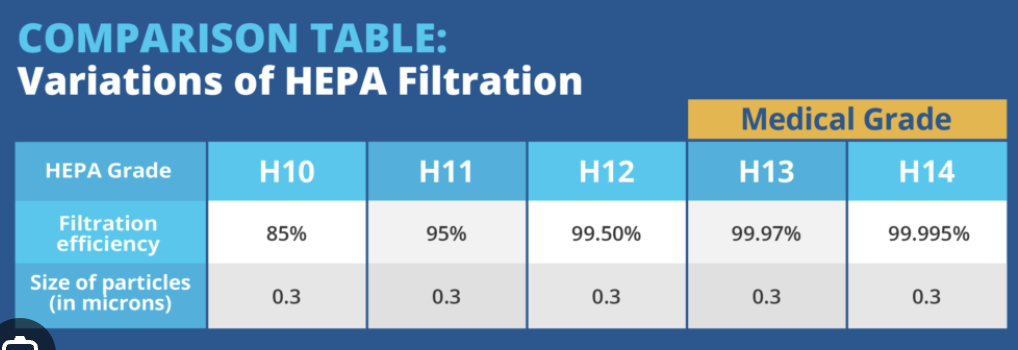

How are HEPA filters classified?

HEPA filters are classified by their filtration efficiency. The standard HEPA filter captures at least 99.97% of particles ≥0.3 microns in size. Higher grades, like ULPA filters, can capture even finer particles.

Different regions have specific standards for HEPA classification. For example, in the U.S., HEPA filters are defined by IEST-RP-CC001.3 standard, while Europe follows the EN 1722 standard, categorizing filters from H13 to H14.

HEPA filters are also classified based on their use, such as industrial, medical, and residential filters. Different applications require different grades of filtration, depending on the required air purity.

What is HEPA H13 Classification?

HEPA H13 Classification: HEPA H13 filters are classified as high-efficiency filters that capture 99.95% of particles as small as 0.3 microns. They are commonly used in cleanrooms, hospitals, and other environments where high air quality is essential.

Application and Standards: In the EN 1722 standard, H13 filters are one of the highest grades, offering excellent particle removal efficiency, making them suitable for critical applications in medical, pharmaceutical, and industrial settings.

What is HEPA filter grade?

The grade of a HEPA filter refers to its filtration efficiency at trapping particles of a specific size. For example, a standard HEPA filter captures at least 99.97% of particles that are 0.3 microns in diameter.

HEPA filters are classified into various grades, such as H13 and H14 under the EN 1722 standard, based on their particle capture efficiency. Higher grades, like ULPA, can trap smaller particles with even greater efficiency.

Different HEPA grades are used in varying environments, with H13 and H14 filters typically found in cleanrooms, laboratories, and medical facilities, where high air quality is crucial for safety and contamination control.

How many types of HEPA filters are there?

H10: A basic level HEPA filter, providing lower filtration efficiency.

H11: A standard filter with medium filtration efficiency for less sensitive environments.

H12: Offers high filtration efficiency, often used in commercial applications.

H13: Offers a very high level of particle filtration, often used in medical and pharmaceutical environments.

H14: Provides the highest filtration efficiency, used in critical cleanrooms and laboratories.

HEPA filters are available in various types, classified based on efficiency, application, and filtration methods.

What are HEPA filters used?

HEPA filters are primarily used in air purifiers to clean indoor air by trapping dust, pollen, mold spores, pet dander, and other airborne particles. They are common in homes, offices, and healthcare settings to improve air quality.

HEPA filters are used in cleanrooms, hospitals, and laboratories to prevent contamination in environments requiring strict air purity, such as pharmaceutical manufacturing, surgery rooms, and electronics production.

How Much Does a HEPA Filter Cost?

Standard HEPA Filters: The cost of a typical HEPA filter for home air purifiers or HVAC systems ranges from $20 to $150, depending on the brand, size, and application.

Industrial and Specialized Filters: For industrial or medical applications, HEPA filters can cost significantly more, with prices ranging from $500 to $5,000 or more, depending on the specifications and efficiency required for the environment.

Why is HEPA So Expensive?

HEPA filters are made from advanced materials that require precise manufacturing processes to ensure high filtration efficiency (99.97% for particles ≥0.3 microns), contributing to their higher cost.

HEPA filters are often used in critical environments, such as cleanrooms and medical facilities, where air quality is vital. Their ability to meet stringent standards for particle removal and durability increases both their price and demand.

What is the Difference Between H13 and H14 HEPA Filter?

The main difference between H13 and H14 HEPA filters lies in their filtration efficiency:

H13 HEPA Filter: Captures at least 99.95% of particles ≥0.3 microns in size.

H14 HEPA Filter: Captures at least 99.995% of particles ≥0.3 microns, offering slightly higher efficiency than H13.

18186671616

18186671616 pengwu1616@gmai.com

pengwu1616@gmai.com

MENU

MENU