MENU

MENUX

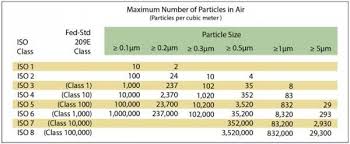

Class 6 Modular Cleanrooms are controlled environments designed to meet specific cleanliness standards as defined by the International Organization for Standardization (ISO) under ISO 14644-1. These cleanrooms are commonly utilized in various industries where controlling airborne particulate contamination is essential, although they have less stringent requirements compared to Class 5 cleanrooms.

Pharmaceutical Manufacturing: Used in some areas of pharmaceutical production where lower cleanliness standards are acceptable but still require control over contamination.

Biotechnology: Suitable for laboratories conducting research and development that do not require the highest levels of particulate control.

Electronics Manufacturing: Used in the production of certain electronic components that are less sensitive to contamination than those produced in Class 5 environments.

Definition

Class 6 cleanrooms are environments that allow a maximum of 35,200 particles (≥0.5 µm) per cubic meter, providin a moderate level of cleanliness suitable for various industries.

Applications

Commonly used in electronics, pharmaceuticals, and medical device manufacturing, where lower levels of contamination are acceptable.

Design Features

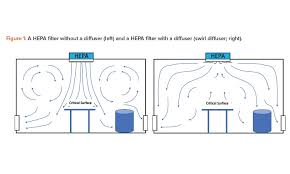

These cleanrooms are built with controlled airflow, HEPA filters, and smooth surfaces to minimize particle generation and facilitate cleaning.

Class 6 cleanrooms are required to maintain a maximum of 35,200 particles per cubic meter for particles that are 0.5 µm in size and larger.

Adhering to these limits is crucial for industries that must meet specific contamination control standards.

Continuous monitoring and regular audits are necessary to ensure compliance with the particle count limits.

Electronics Manufacturing: Class 6 cleanrooms are essential for producing electronic components where dust can cause significant issues.

Pharmaceutical Production: They are used in the manufacturing and packaging of pharmaceuticals to ensure product safety.

Biotechnology: Used for research and development processes that require controlled environments to prevent contamination.

1.Class 6 cleanrooms utilize laminar airflow systems to ensure unidirectional airflow, reducing the risk of contamination from airborne particles.

2.These cleanrooms typically require 15 to 30 air changes per hour to maintain cleanliness and air quality.

3.Maintaining positive pressure relative to surrounding areas helps to prevent the ingress of contaminants.

Class 6 cleanrooms typically operate in a temperature range of 20°C to 25°C (68°F to 77°F) to ensure product integrity and worker comfort.

Humidity levels are usually maintained between 30% and 50% to minimize static electricity and prevent product degradation.

Continuous monitoring systems are essential to ensure that temperature and humidity remain within specified limits.

Wall Panels: Common materials include stainless steel, fiberglass, and painted metal, chosen for their durability and ease of cleaning.

Flooring: Smooth, non-porous flooring materials are used to facilitate cleaning and maintain a sterile environment.

Ceiling Systems: Designed to hold HEPA filters and meet cleanliness standards while allowing for easy access to maintenance.

1.Regular Cleaning:

Implementing strict cleaning protocols, including daily and weekly cleaning schedules, is essential to maintain cleanliness.

Regular maintenance of HVAC systems and air filters is crucial for optimal performance and air quality.

3.Staff Training:

Ensuring that all personnel are trained in cleanroom protocols helps to minimize contamination risks.

1.Flexibility

Modular cleanrooms can be easily reconfigured or expanded to accommodate changing business needs without extensive downtime.

2.Cost Efficiency

They often require less time and investment compared to traditional construction methods, making them a cost-effective solution.

3.Quick Installation

Modular systems can be installed more rapidly, allowing businesses to begin operations sooner.

Class 6 cleanrooms typically maintain noise levels below 60 dBA to ensure a comfortable working environment for personnel.

Using low-noise machinery and soundproofing techniques can help meet these noise level requirements.

ISO Certification:

Class 6 cleanrooms should comply with ISO 14644-1 standards, which specify the cleanliness levels and particle counts for different classes.

Validation Process:

Regular validation and certification processes must be conducted to ensure the cleanroom meets the required standards.

Third-Party Audits:

Engaging third-party auditors can provide an unbiased assessment of compliance with cleanroom standards and regulations.