MENU

MENUX

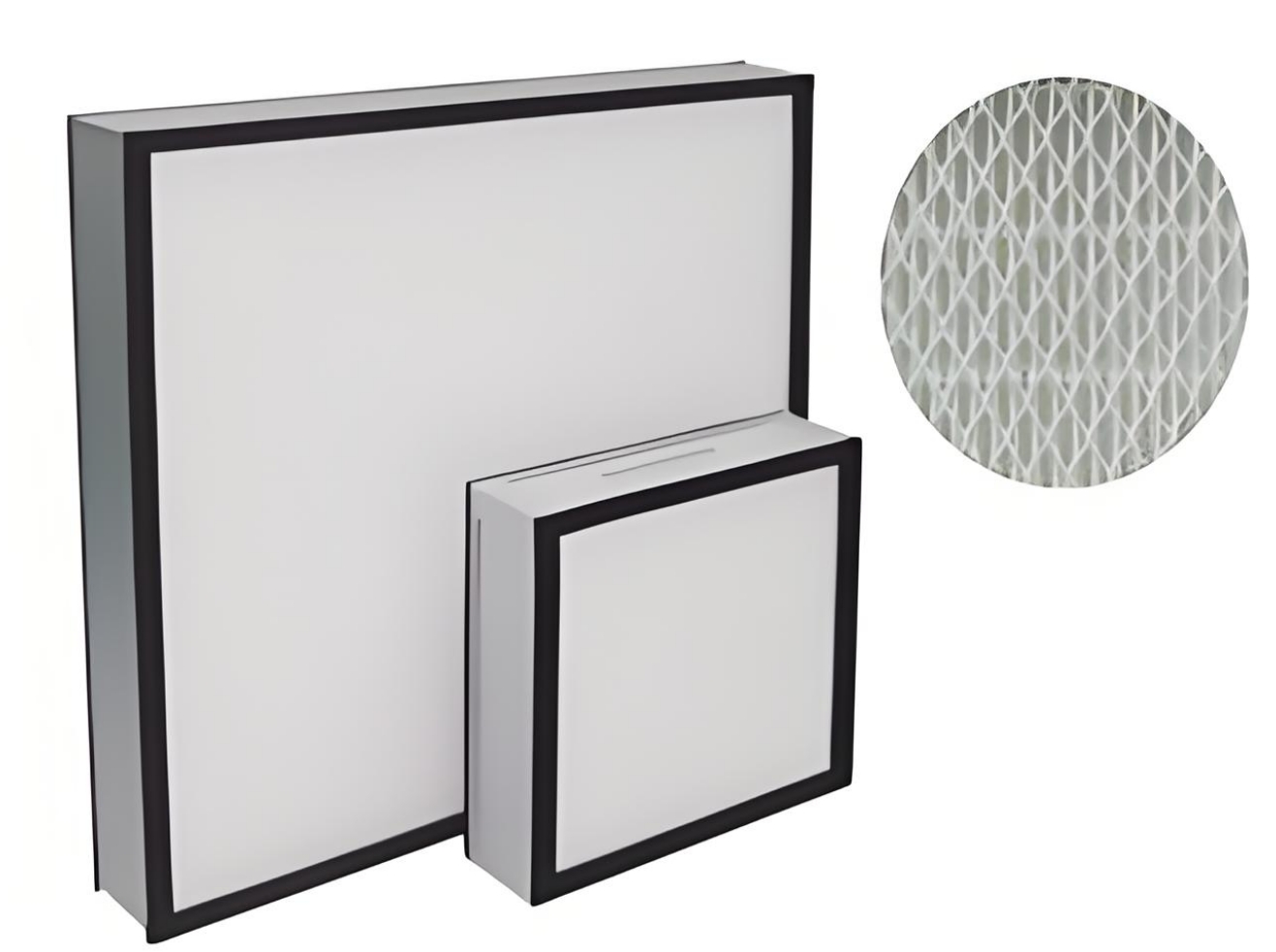

With its excellent design and performance, the compartmentless filter has become an indispensable part of modern air purification systems. It not only meets the strict requirements of space, weight and energy consumption, but also excels in enhancing airflow and filtration efficiency. For industries and occasions that require efficient air purification, the panelless filter is undoubtedly an ideal choice. Through reasonable installation and maintenance, its advantages can be fully utilized to provide users with a cleaner and healthier air environment.

Separatorless filter replaces the aluminum foil in the traditional separator filter through hot melt adhesive technology to form an effective separation of the filter material. Due to the elimination of the structural design of the partition, this filter excels in thickness, performance and airflow. For example, a 50mm thick non-separator filter can achieve the same filtration performance as a 150mm thick separator filter, a feature that makes the non-separator filter especially prominent in space-limited application scenarios.

Superior airflow performance: MPT 90mm thick frame HEPA filter can achieve 1.3 times or even 2 times the airflow of 150mm thick standard resistance type with partition under the same filtration area and efficiency. This makes the non-septum filter especially effective in high air volume demand occasions.

Lightweight design: The smaller and lighter frame design of the non-septum filter helps to reduce labor intensity during installation and handling, especially in space-constrained environments.

Flexible installation and maintenance: thanks to its good product design, the filter can be easily installed, replaced and upgraded, which greatly improves the maintainability of the system.

Improved filtration efficiency: Especially with the design of 55mm, 70mm and 75mm pleat heights, it can effectively reduce resistance, improve filtration efficiency and outperform other septum-free products in the market.

Energy-saving benefits: the low resistance feature of the non-septum filter can bring significant energy-saving effects to the air purification system, in line with today's strict requirements on energy consumption.

The non-separator filter is suitable for environments with humidity up to 100% and temperature up to 85℃, and thus is widely used in many industrial and scientific research fields with high humidity and high temperature.

Special attention should be paid to the following points when installing the non-separator high-efficiency filter:

Cleaning before installation: It is vital to ensure that the system and the clean room are clean. A comprehensive cleaning should be carried out before installation, using a vacuum cleaner equipped with an ultra-clean filter bag to avoid any contaminants affecting the filtration effect.

Leak testing: In cleanrooms with cleanliness levels equal to or higher than Class 100, on-site leak testing must be performed prior to installation to check for filter breakage and leakage. Leakage testing should also be carried out after the installation of filters in clean rooms of all levels to ensure the quality of sealing.

Resistance deployment: the difference in resistance of different filters will affect the balance of air volume and the stability of airflow. Filters with similar resistance should be arranged in the same room to avoid uneven airflow caused by resistance differences.

Follow the norms: Especially in the unidirectional flow clean room, the filter resistance requirements are more stringent, and should follow the relevant construction and acceptance specifications to ensure the normal operation of the system and filtration effect.