MENU

MENUX

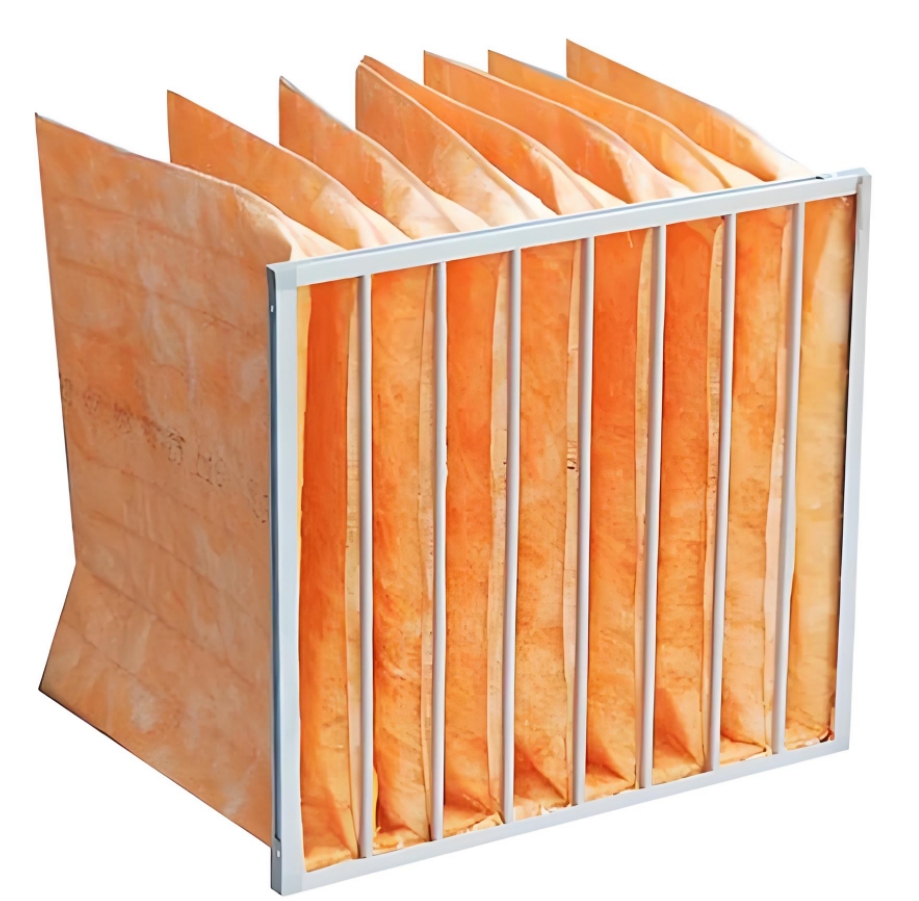

Fiberglass medium-effect bag filters are popular in the air purification field due to their unique design and excellent performance. Its bag structure ensures that the airflow evenly fills the entire filter bag, effectively preventing overcrowding or leakage of the bag and significantly reducing air resistance while maximizing dust holding capacity. This design not only improves filtration efficiency, but also extends the service life of the filter.

Glass fiber medium-effect bag filters are widely used in industrial and commercial air-conditioning systems, especially in environments that require high efficiency air filtration, such as hospitals, pharmaceutical factories, electronic manufacturing and other industries, to provide a highly efficient solution for dust trapping, and to safeguard the quality of air and the normal operation of equipment.

1. Aesthetically pleasing, sturdy and durable

The filter has a simple and beautiful design, and the frame is made of galvanized sheet or aluminum alloy to ensure that it is sturdy and durable.

2. Large airflow and low resistance

Its unique design makes the filter effectively reduce air resistance while ensuring a large air volume, which improves the system's operating efficiency.

3. Large effective filtration area and high dust holding capacity

The glass fiber medium-effect bag filter has a large effective filtration area, which can capture more dust and prolong its service life.

4. High efficiency class

The efficiency grades of this filter include M5(F5), M6(F6), F7, F8, F9, etc. to meet the filtration needs of different environments.

Filter Media: Adopting high performance synthetic fiber with good filtration effect.

Frame: galvanized plate or aluminum alloy can be used to ensure a stable structure.

Sealing strip: PE sealing strip is used to provide good sealing performance.

Fiberglass medium-effect bag filter is widely used in commercial and industrial ventilation and air-conditioning systems, especially in the air supply system of paint spraying rooms, pharmaceutical factories, operating rooms and electronic manufacturing, etc. It plays an important role in filtration.

Maximum temperature: 100℃.

Maximum humidity: 100%RH (non-condensing condition)

Compared with ordinary bag filters, fiberglass medium-effect bag filters are designed with hard fused crimps, which can keep the filter bag in a firm state. This makes the filter virtually unaffected when the blower stops, whereas regular meltblown cotton material can become disorganized due to softening. When the fan is restarted, the shaking of the glass fiber filter bag is significantly lower than that of domestic meltblown materials, thus effectively reducing the risk of secondary contamination.

In summary, with its superior performance and design, the glass fiber medium-effect bag filter has become an ideal choice for high-efficiency air filtration, providing a reliable air quality guarantee for a number of industries.