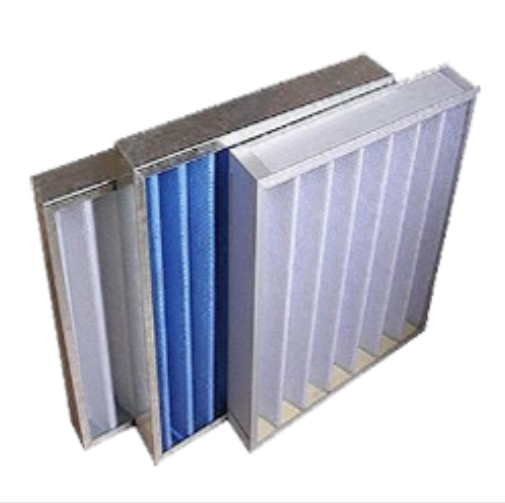

Primary filter

Primary filter is the primary filter in air conditioning system, which is mainly used to filter dust particles above 5μm, and is one of the key components to ensure air quality and normal operation of the system. According to different designs and materials, primary filters can be categorized into plate type, folding type and bag type to meet the needs of different air conditioning systems.

Frame material: The frame material of the preliminary filter is diversified, including paper frame, aluminum frame, galvanized iron frame, etc., which has different durability and applicable range, and can adapt to the use of different environments and working conditions.

Filter material: The filter material of the primary effect filter is rich in variety, including non-woven fabric, nylon mesh, activated carbon filter material, metal porous mesh, etc., which have different filtration efficiencies and trapping capacities, and the suitable filter material can be selected according to the specific requirements.

Protective mesh: primary filters are usually equipped with protective mesh, and common protective mesh includes double-sided sprayed wire mesh and double-sided galvanized wire mesh, which can effectively prevent the filter from being damaged and extend the service life of the filter.

Your Reliable Manufacturer of Primary filter

Product features of the filter:

Inexpensive, light weight, good versatility, compact structure.Mainly for:

Pre-filtration for central air conditioning and centralized ventilation systems

Pre-filtration for large air compressors

Clean return air system

Pre-filtration of local high-efficiency filtration device

High temperature resistant air filter with stainless steel frame, high temperature resistant 250-300℃ filtration efficiency.

This kind of efficiency filter is commonly used in the primary filtration of air-conditioning and ventilation systems, and is also suitable for simple air-conditioning and ventilation systems that only need primary filtration.

G series coarse-effect air filters are divided into eight varieties, namely: G1, G2, G3, G4, GN (nylon mesh filters), GH (metal mesh filters), GC (activated carbon filters), GT (high-temperature resistant coarse-effect filters).

Filter application industry:

Operating room, laboratory purification and air conditioning system: in operating rooms and laboratories, places with extremely high requirements for air quality, high-efficiency filters play a key role. Through high-efficiency filters, particles, bacteria, viruses and other harmful substances in the air can be effectively removed to ensure that the air in operating rooms and laboratories is clean and sterile, providing a safe environment for surgery and experiments.

Dust-free workshop for food and pharmaceuticals: In the production process of food and pharmaceuticals, a dust-free environment is crucial to product quality and safety. High-efficiency filters can effectively filter particles and bacteria in the air, ensure clean air in the production workshop, prevent outside contaminants from entering, and safeguard the quality and hygienic standards of food and drugs.

Electronic and optical clean room: In the electronic and optical industries, air quality and cleanliness are highly required. High-efficiency filters can remove fine dust, electrostatic particles and other particles in the air that are harmful to electronic components and optical equipment, ensure the cleanliness of the production environment, and improve product quality and production efficiency.

Precision Electronic Instrument Factory: In the field of precision electronic instrument manufacturing, high-efficiency filters are widely used in production workshops and laboratories. By filtering fine dust, bacteria and other harmful substances in the air through high-efficiency filters, the cleanliness of the production environment is maintained to ensure the production quality and stable performance of precision electronic instruments.

Filter leak check:

Before the installation of high-efficiency filters in clean rooms with a cleanliness level equal to or higher than 100, on-site leakage testing must be carried out, focusing on checking the quality of the filters themselves, such as whether they are damaged or leaking. All levels of clean room, are required to be installed on the high-efficiency filter for leakage, in the current specification does not give the number of inspections, you can set a proportion of the installation of leakage detection focuses on the air filter frame sealing quality.

Primary filter cleaning method:

Open the inhalation grille in the unit by holding down the buttons on either side and gently pulling down; the

Drag the hook on the air filter to pull the unit out in a diagonal downward direction.

Remove the dust with a vacuum cleaner or rinse with warm water.

If there is too much dust, you can use a soft bristle brush with neutral detergent to clean, clean the water after shaking dry, placed in a cool place to dry.

Never use more than 50 ℃ of hot water for cleaning, so as to avoid the phenomenon of equipment color or deformation, and do not bake dry on the fire.

After the cleaning is completed, be sure to install the equipment in a timely manner, the installation of the equipment will be hung on the upper part of the protrusion of the inhalation grille, and then fixed on the inhalation grille, the back of the inhalation grille convex handle slowly sliding inward until the whole device is pushed into the grille; the last step is to close the inhalation grille, the last step is to close the inhalation grille.

The last step is to close the suction grille, which is exactly the opposite of the first step, press and hold the filter signal reset button on the control panel, at this time the cleaning reminder sign will disappear.

Another reminder, if the primary filter used in the environment of too much dust, then the number of cleaning should be increased depending on the circumstances, generally half a year is appropriate.

- Video

- Workshop

- Data sheet

- Material certificate

Nylon mesh primary filter

Nylon mesh pre-filter, English name is called “nylon mesh pre-filter” frame: aluminum alloy frame or nylon wrapped edge. Equipment for filtration Nylon mesh pre-filter, the English name is “nylon mesh pre-filter” frame: aluminum alloy frame or nylon wrapping.

Bag Type Primary Filter

Bag primary filter is a kind of high-efficiency air filtration equipment, which is widely used in environments requiring strict air quality control, such as food, medicine, electronics and new energy industries.

Folded Activated Carbon Primary Filter

Folding activated carbon filter is a highly efficient air filtration equipment widely used in various places where air purification is required, such as laboratories, dust-free workshops, pharmaceutical and food factories. I

Folding Primary Filter

Primary folding filter is a kind of air filtration equipment widely used in air conditioning system, specially designed for removing airborne particles larger than 5.0μm, dust and all kinds of suspended matters.

High Temperature Primary Filter

High-temperature resistant primary filter is a kind of air filtration equipment specially designed for high-temperature environments, which is widely used in hot-air high-temperature ovens, painting factories and other places where strong air purification is required.

Replaceable (washable) primary filters

Primary filters play a vital role in central air-conditioning and centralized air supply systems, mainly used to filter dust particles larger than 5 microns in the air, and protect the performance and life of the next level of filters.

Metal mesh primary filter

Primary metal mesh filter is a common air filter, which is mainly composed of metal wire mesh and outer frame. It is mainly used to filter large particles in the air, such as dust, dust, shed hair and pet dander, etc.

Products Video

FAQ

What is a primary air filter and how does it function?

A primary air filter is a component of heating, ventilation, and air conditioning (HVAC) systems that is designed to remove large particles from the air before it passes through the system. These filters are typically the first line of defense against contaminants and are used in both residential and commercial applications to enhance indoor air quality and protect HVAC equipment.

How do I choose the right primary air filter for my HVAC system?

1. Determine Filter Size

Check Existing Filter Dimensions: Measure the dimensions of your current air filter (length, width, and thickness) or consult the HVAC system manual.

2. Understand Filter Ratings

G1,G2,G3,G4,G5,G6,G7

3. Filter Type

Nylon mesh primary filter

Folded Activated Carbon Primary Filter

Folding Primary Filter

High Temperature Primary Filter

Replaceable (washable) primary filters

Metal mesh primary filter

By understanding these factors—size, MERV rating, material, airflow compatibility, and maintenance needs—you can select the right primary air filter that meets both the needs of your HVAC system and the air quality requirements of your environment.

What are the benefits of using a primary air filter?

1. Pre-filtration of large dust particles

Remove particles: Primary air filters effectively capture dust, pollen, pet dander, mold spores and other airborne particles.

2. Protect HVAC equipment

This can reduce breakdowns and extend cleanrooms equipment life. Save on maintenance costs: Keeping your system clean reduces the need for frequent repairs and maintenance, ultimately saving on operating costs.

3. Improve energy efficiency

Optimize airflow: A clean primary air filter ensures that air can flow freely through the HVAC system. When filters become clogged or dirty, airflow is restricted, causing the system to work harder to maintain the desired temperature, resulting in higher energy consumption.

How often should I replace my primary air filter?

| Filter Type | Replacement Frequency | Factors Influencing Frequency |

| Standard Disposable Filters | Every 1 to 3 months | - Household size (more occupants/pets) |

| - High dust or pollen areas | ||

| - System usage (continuous vs. seasonal) | ||

| High-Efficiency Filters (MERV 11+) | Every 6 to 12 months | - Similar factors as standard filters |

| - Cleaner air quality in environments | ||

| Washable Filters | Every 3 to 6 months | - Frequency of cleaning and air quality |

| - Household activities (construction, pets, etc.) | ||

| Visual Inspection | As needed | - Check for dirt and debris; replace if visibly dirty |

| Smart HVAC Systems | As indicated by system alerts | - Regular checks based on system notifications |

Can a primary air filter improve indoor air quality?

Yes, a primary air filter can improve indoor air quality by filtering out larger dust particles, pollen, and debris, thus reducing their presence in the air. However, while it serves as a pre-filter and contributes to a better indoor environment, it may not achieve high cleanliness standards on its own. For optimal air quality, it is often necessary to use a secondary air filter or a higher-efficiency filter to capture smaller particles and allergens.

How do I install a primary air filter in my air conditioning unit?

Tools and Materials Needed

New primary air filter (make sure it is the correct size and type for your unit)

Screwdriver (if needed)

Vacuum cleaner (optional, for cleaning)

Clean cloth (optional, for wiping surfaces)

Installing a primary air filter in your air conditioning unit is a straightforward process, but it's essential to follow the correct steps to ensure proper airflow and filtration.

Which professional Primar filter manufacturer is good?

Here are two well-known professional primary filter manufacturers that are highly regarded in the industry:

Deiiang

Camfil is a global leader in air filtration solutions, known for producing high-efficiency filters, including HEPA and ULPA filters. They specialize in creating advanced filtration systems for a wide range of industries, including pharmaceuticals, cleanrooms, and industrial applications. Their products are designed for optimal air quality and energy efficiency.

3M

3M is another trusted name in the air filtration industry, offering a broad range of high-performance filters and systems. Their filtration products are widely used in cleanroom environments, industrial settings, and HVAC systems. 3M is known for innovation and quality, ensuring that their filters meet stringent standards for air purity and reliability.

18186671616

18186671616 pengwu1616@gmai.com

pengwu1616@gmai.com

MENU

MENU