Standard Clean Bench

A clean bench provides a sterile working environment by directing filtered air across the surface, ensuring that airborne contaminants are prevented from interfering with the product or process. Clean benches typically feature an open workspace with a built-in air filtration system that can deliver continuous air flow.

Types of Clean Benches:

Laminar Flow Clean Bench: Ensures that air flows in a single direction, minimizing contamination risk.

Vertical Flow Clean Bench: Air flows downward from the ceiling, ensuring a clean workspace.

Horizontal Flow Clean Bench: Air flows from the back of the bench to the front, typically used for more substantial items.

Your Reliable Manufacturer of Standard Clean Bench

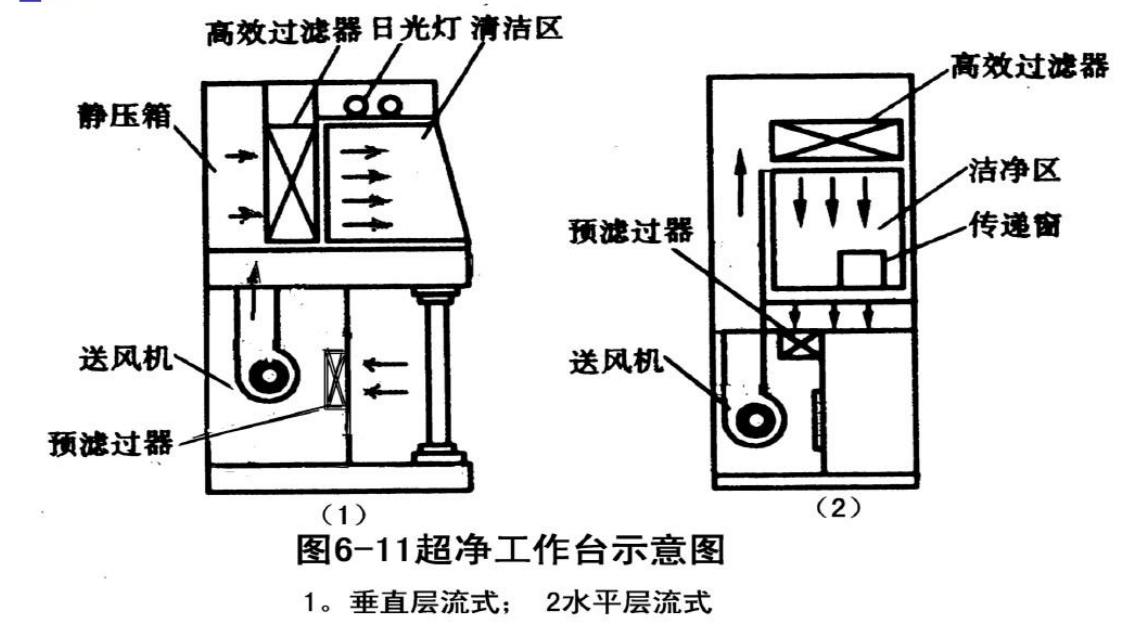

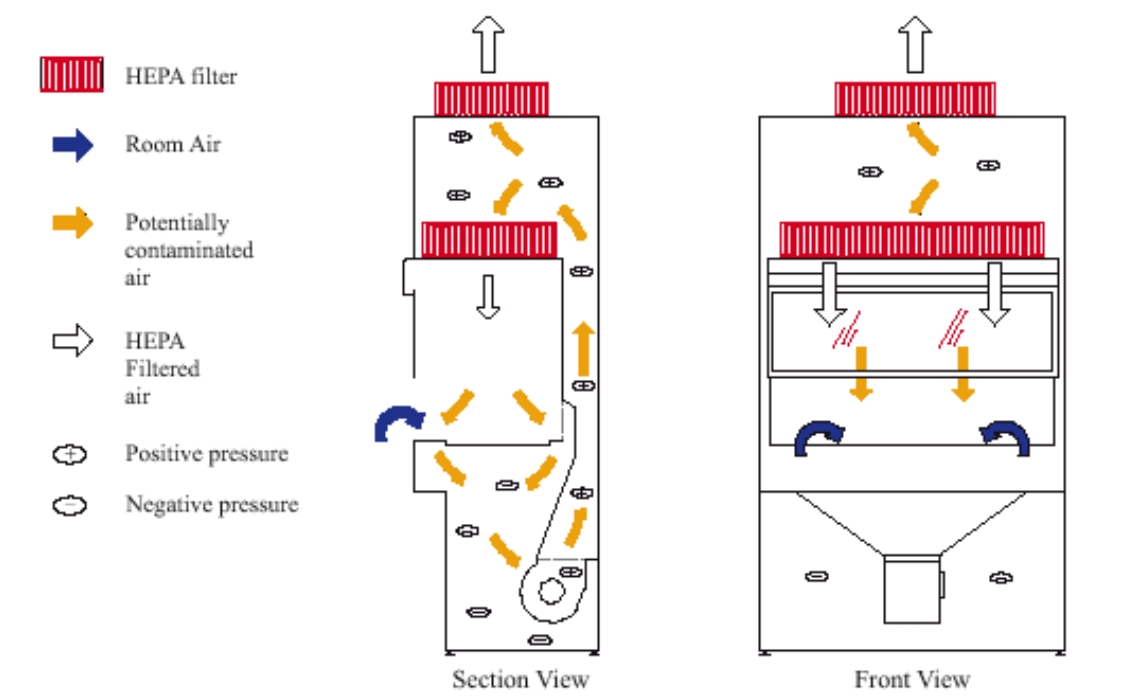

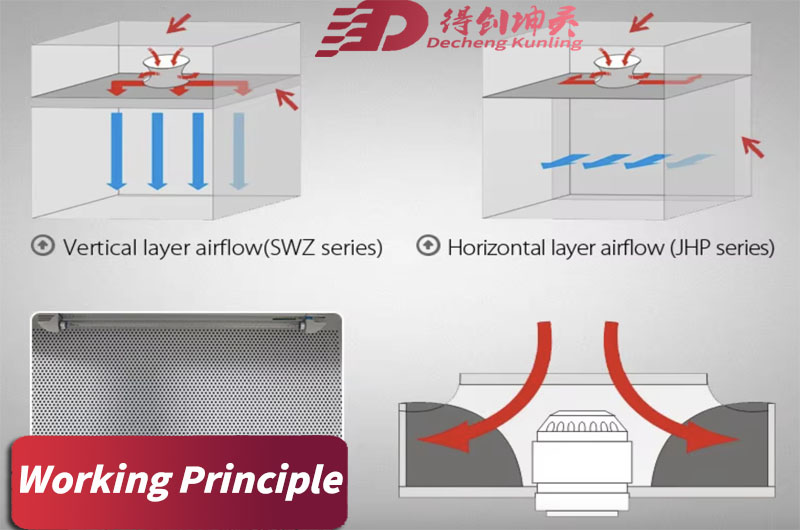

Working Principle

Ultra-clean bench principle is in a specific space, the indoor air through the pre-filter primary filtration, by small centrifugal fan pressed into the static pressure box, and then through the air high-efficiency filter secondary filtration, from the air high-efficiency filter out of the air out of the surface of the clean air flow with a certain and uniform cross-section of the wind speed, you can exclude the original air in the work area, dust particles and biological particles away to form a sterile and high-clean working environment.

Classification

Ultra-clean workbench from the number of operators: divided into single workbench and double workbench; ultra-clean workbench from the structure: divided into conventional and new push-pull and self-circulating type (vertical flow only).

Ultra-clean bench according to the direction of airflow is divided into vertical laminar flow ultra-clean bench (vertical flow clean bench) and horizontal laminar flow ultra-clean bench (horizontal flow clean bench), vertical flow bench due to the fan at the top of the so noisy but the wind is blowing vertically, more in the pharmaceutical engineering so as to ensure the health of the people; horizontal flow bench noise is relatively small wind to the top of the bench, so the wind is blowing vertically. Horizontal flow clean bench noise is relatively small wind to the outside so more used in the electronics industry, the impact on health is not great.

Ultra-clean bench according to the operating structure is divided into single-sided operation and bilateral operation of two kinds. According to its use can be divided into general ultra-clean bench and biological (pharmaceutical) ultra-clean bench.

Usage

Ultra-clean bench is a one-way flow air purification equipment that provides a local dust-free and sterile working environment. Applicable to medicine and health, biological medicine, food, medical science experiment, optics, electronics, aseptic chamber experiment, aseptic microbial testing, plant inoculation and other needs of local clean and sterile working environment of scientific research and production departments. It can also be connected to the assembly line with low noise, mobility and other characteristics. Its use to improve process conditions, improve product quality and increase the rate of finished products have good results.

Precautions

The service life of the ultra-clean table is related to the cleanliness of the air. In the temperate regions of the ultra-clean table can be used in the general laboratory, but in the tropical or subtropical regions, by the amount of pollen in the atmosphere, or dusty areas, the ultra-clean table is appropriate to be placed in a better double door indoor use. Under no circumstances should not be ultra-clean table air inlet cover to the open door or window, so as not to affect the service life of the filter.

Ultra-clean bench can also be suspended in the ultraviolet lamp, but should be installed in the lighting outside the hood, and staggered lighting arrangement, so that the work does not interfere with the lighting. Do not install the ultraviolet lamp into the lighting lampshade (glass plate) inside, because the ultraviolet light can not penetrate the glass, its lamp is a quartz glass, rather than silicate glass.

Difference between ultra-clean bench and biological safety cabinet:

|

|

- Video

- Workshop

- Data sheet

- Material certificate

Vertical Flow Ultra-clean Bench

Vertical flow ultra-clean bench is a kind of ultra-clean bench that sends air vertically from top to bottom, with high efficiency filtration, clean and dust-free, which can provide a sterile working environment, and is widely used in the fields of biopharmaceuticals, healthcare, chemical experiments and so on.

Horizontal Flow Ultra-clean Bench

Horizontal flow ultra-clean bench is a kind of aseptic purification equipment that adopts high-efficiency filtration technology and airflow purification system to flow air horizontally and uniformly from the top to the bottom.

Products Video

FAQ

How Do I Use a Clean Bench?

Using a clean bench properly involves ensuring that it is set up, maintained, and used in ways that minimize contamination risks. This includes keeping the workspace organized, using sterilized tools, and following proper protocols to maintain airflow and cleanliness.

1. Preparation:

Always clean and sterilize the bench before use.

2. Sterile Tools:

Use only sterilized equipment and materials inside the clean bench.

3. Minimize Disruptions:

Avoid unnecessary movements to ensure laminar airflow is not disturbed. Clean after each use, checking airflow status and filter conditions regularly to ensure continuous cleanliness.

What is the Purpose of a Clean Bench in Laboratories?

Contamination Prevention

A clean bench is designed to provide a sterile working environment, preventing contamination of sensitive materials or processes. This is essential in fields such as pharmaceuticals, biotechnology, and electronics, where even minor contamination can compromise results.

Purpose in Specific Processes:

1. Sterile Work Environment:

A clean bench ensures that sterile conditions are maintained for handling sensitive materials, such as pharmaceutical drugs, biological cultures, or semiconductor components.

2. Efficient Workflow:

By controlling particulate contamination, clean benches allow researchers to focus on tasks with minimal risk of contamination, enhancing productivity. Clean benches are particularly beneficial for small-scale, localized procedures that don’t require an entire clean room.

3. Key Applications in Research and Industry:

Clean benches are widely used in cell culture, microbiological research, and sensitive electronics assembly. They ensure that sterile workspaces are consistently maintained, reducing contamination and product failure.

What is the Difference Between a Laminar Flow Hood and a Clean Bench?

List of Key Differences:

Airflow Direction:Laminar flow hoods have controlled airflow in one direction, either horizontal or vertical.

Workspace Design:Clean benches typically offer more space for larger items compared to laminar flow hoods.

Sterility Focus:Both systems provide sterile environments, but clean benches allow for a wider range of tasks.

Usage Scale:Laminar flow hoods are often used for small-scale, precision tasks, while clean benches are for larger tasks requiring less enclosed space.

Flexibility:Clean benches offer greater flexibility in terms of accessibility and the types of materials or processes that can be handled.

- Cost:Laminar flow hoods are generally more expensive due to their specialized design and limited workspace.

A laminar flow hood and a clean bench

are both designed to provide contamination-free workspaces, but they are used in different applications and environments. The main difference lies in their airflow systems and the level of protection they offer.

Laminar Flow Hoods

are designed to direct filtered air in a uniform, uninterrupted flow over the workspace, preventing contamination from airborne particles. These systems can be either horizontal or vertical in airflow direction. The laminar flow hood is typically used for small-scale tasks, such as working with sterile media or small samples.

Clean Benches

on the other hand, focus on providing a localized sterile environment with clean, filtered air flowing over the workspace. However, unlike laminar flow hoods, clean benches typically have a wider open area for handling larger items or materials. Clean benches are less restrictive than laminar flow hoods and are ideal for tasks like microbiological work or assembling small electronic components.

In short, laminar flow hoods are typically more enclosed and intended for sterile work with small samples, while clean benches offer a more open, but still controlled, workspace for a wider range of applications.

How Do You Maintain a Clean Bench?

1. Routine Cleaning:

Clean the bench regularly with sterilized wipes to prevent any accumulation of dust or contaminants.

2. Check Airflow and Filters:

Regularly inspect the airflow and change filters as required, typically every 6-12 months depending on usage.

3. Sterilize Equipment:

All tools and materials should be sterilized before placement on the clean bench to maintain sterile conditions.

4. Proper Air Circulation:

Ensure that airflow is not blocked, and the bench is used in a well-ventilated environment to maintain proper filtration and airflow.

Regular checks of the bench’s functionality and cleaning ensure its optimal performance, making it a reliable tool for sensitive laboratory procedures. Ensure that all surfaces are wiped clean using sterile solutions, and monitor the air quality to maintain a high level of contamination control. Proper maintenance is key to the longevity and performance of the clean bench in laboratories.

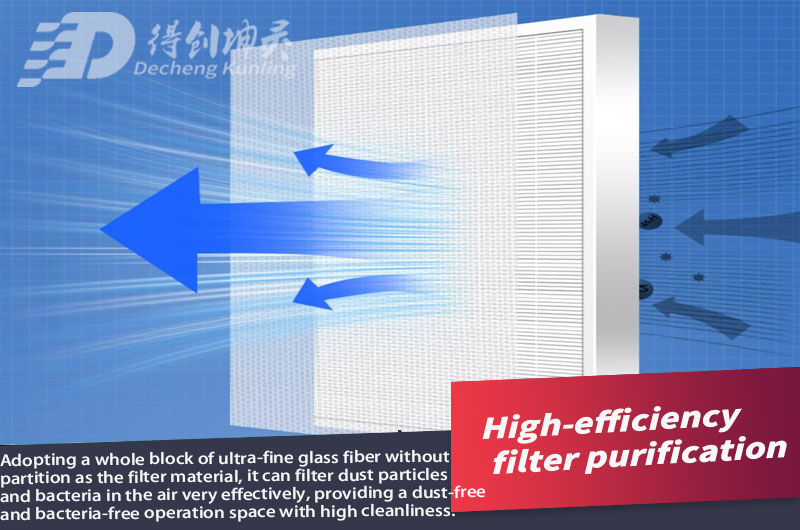

What Type of Filter Does a Clean Bench Use?

A clean bench typically uses a HEPA filter** (High-Efficiency Particulate Air filter) or **ULPA filter(Ultra Low Penetration Air filter) to ensure the air is free from particulate contamination.

HEPA Filters

HEPA filters are widely used in clean benches because they are capable of capturing 99.97% of airborne particles as small as 0.3 microns. These filters work by forcing air through dense fiber mats that trap dust, bacteria, and other particulate matter.

HEPA filters are classified into various grades based on their efficiency and the size of particles they can filter out. Clean benches typically use H13 or higher grade HEPA filters. The efficiency of these filters ensures that the workspace remains sterile, preventing contamination during sensitive tasks.

Maintaining the performance of a HEPA filter requires periodic checks and replacements. Over time, filters lose their efficiency due to clogging by trapped particles, which is why regular maintenance is essential for continued protection and optimal air quality.

ULPA Filters

ULPA filters are more efficient than HEPA filters, capturing up to 99.999% of particles as small as 0.12 microns. They are often used in applications that require an even higher level of air purity.

What Are the Different Types of Clean Benches?

Clean benches come in several configurations, each suited to specific laboratory needs. They differ mainly in airflow direction, construction, and intended application.

Laminar Flow Clean Bench

This type of clean bench directs a constant stream of filtered air in one direction, either horizontally or vertically. It provides a sterile workspace by preventing contaminants from entering.

Vertical Flow Clean Bench

Vertical flow clean benches have a downward air pattern, making them suitable for applications where contamination from above might be a concern. They are typically used in microbiology labs.

Horizontal Flow Clean Bench

Horizontal flow clean benches direct air across the workspace, providing a horizontal barrier to contamination. This design is ideal for handling large items without obstruction from the airflow.

What Industries Use Clean Benches?

Clean benches are essential in many industries where contamination control is crucial for product integrity or research accuracy. These industries rely on clean benches to maintain sterile conditions.

Pharmaceutical Industry

In pharmaceutical manufacturing, clean benches are used to prepare sterile formulations, handle drug components, and conduct quality control testing. They help ensure the drugs are free of contaminants, which is critical for patient safety.

Biotechnology and Research

1. Clean benches are commonly used in biotechnology labs for cell culture, genetic research, and microbiological studies.

2. These labs require controlled environments to maintain sterile conditions for accurate research and experimental outcomes.

Semiconductor and Electronics Manufacturing

Clean benches are also integral in the electronics industry, where contamination from dust or particles can lead to product failure. The production of microchips and other electronic components demands precise contamination control to avoid defects.

Medical Device Manufacturing

Clean benches in medical device production facilities ensure that parts and components remain free of contamination during the assembly process, which is crucial for patient safety and regulatory compliance.

18186671616

18186671616 pengwu1616@gmai.com

pengwu1616@gmai.com

MENU

MENU